40 years on the packaging market

Products

Folplast Stretch Hood

Stretch hood (cold stretched wrapping) is one of the most dynamically expanding unifying packaging technology (with pallets) on the market.

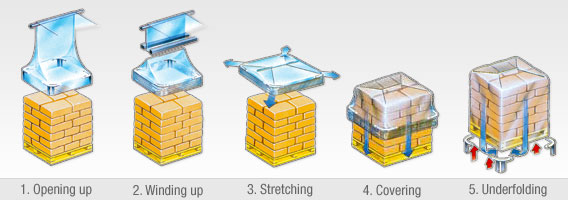

The principle is that after opening up the tubular stretch hood and mechanically stretching it at 4 places it is pulled over the unit pallet load (see figure). Due to its elastomer feature, the packaging material “tries” to resume its previous status that it had before stretching and thus an even clamping force is generated around the entire circumference of the pallet.

The force that holds together the unit load is substantially higher than in case of using conventional shrink hood or mechanical stretch film. Another advantage of the technology is that there is no need for an expensive and energy demanding shrink tunnel or heat tunnel, which represents at least 30-40% energy saving. Furthermore, the advantages of the technology are summarised in the table shown below:

| Performance criteria | Stretch hood | Shrink hood | Stretch film |

|---|---|---|---|

| Holding strength | Highest | High | High |

| Energy requirement | Low | High | Low |

| Roll change | Fewest | Few | Many |

| Material consumption | Fewest | Few | High |

| Optical features | Excellent | Good | Poor |

| Manual packaging | No | Yes | Yes |

| Automation | Yes | Yes | Yes |

| Water tightness | Yes | Yes | No |

| Packaging speed | ~200 pcs/hr | ~100 pcs/hr | ~100 pcs/hr |

| Safety | High | Medium | Medium |

| Recyclability of the packaging material | Excellent | Excellent | Poor |

| Investment costs | Medium | High | Low |

| Printability | Excellent | Excellent | Poor |

| Pallets of different sizes | Suitable | Unsuitable | Suitable |

Scope of application*

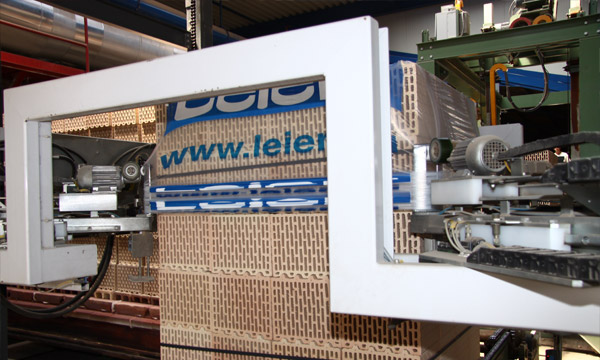

- building industry (cement, bricks, tiles, etc.)

- collective packaging of food industrial products (soft drinks, canned food, etc.)

- individual or unifying packaging of industrial and household appliances.

*for products on pallets / EUR pallets only

Note: you can find useful information about the warehousing and storage of the products under "Material Storage Requirements"!

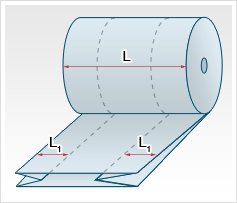

Stretch hood products are manufactured in the following dimensions:

| Width [L] | 600 mm - 1.800 mm |

|---|---|

| Side gusset (folding) [L1] | 100 mm - 400 mm |

| Circumference [Kmax] | 5200 mm |

| Circumference [Kmin] | 2000 mm |

| Thickness [v] | 0,04 mm - 0,2 mm |

Note: circumference = 2L + 4L1

Request a quotation>Options:

- printing (1-6 colour flexographic printing)

- colouring

- environmental “recyclable" marking

- anti-static

- slippery surface

- UV stable (6, 12 months)